top of page

Lithium-ion Battery Testing Chamber

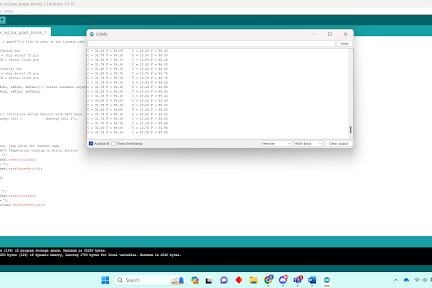

Figure 5: Output Results of the Thermocouples.

Blog Post #5

Work Period December 11th - February 3rd:

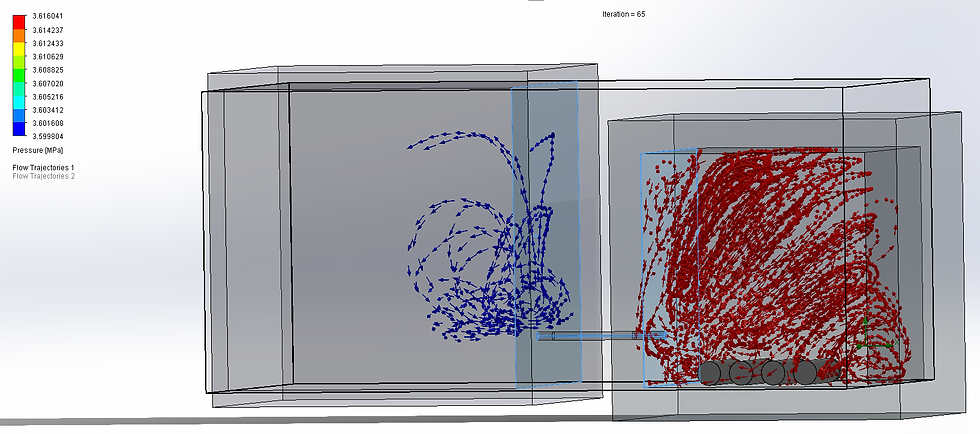

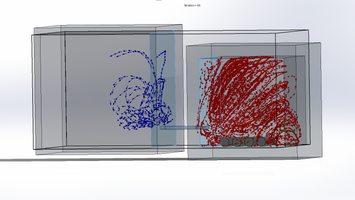

During the work period of December 11th - February 3rd the team began navigating the process of purchasing materials and instrumentation. Some notable items that have already been acquired include the thermocouples, the electromagnetic lock, and the relays which will be included in the control system. Following the completion of the finalized shop drawings and a meeting with the UH machinist, the team is currently working on selecting a stainless steel vendor to acquire the materials required for chamber fabrication. At the moment, the vendor Metal Supermarkets will be the vendor chosen as it is local allowing for the materials to be picked up in person. Furthermore, based on the quotes from various vendors, it is the cheapest. The team is currently in the process of finalizing quote information with Metal Supermarkets and plans to place an official order in the next few days. Figures 1 and 2 show a quote that was received from MetalSupermarket. Also during this work period, the team finalized the CFD gas flow analysis. Figure 3 shows a preview of the results from the CFD analysis such as the pressure difference between the two volumes. This has allowed the team to simulate the relationship between the gas and pressure changes within the chamber while the battery tests are taking place.

At the moment, the team is working towards beginning the fabrication process of the 10” x 10” x 10” battery testing chamber. When speaking to the the UH machinist, the team was told that the chamber would be completed by the end of February and at the latest, the first week of March. This will allow for the next major step of the project to begin which consists of integrating the measuring instruments and Arduino microcontroller that will be used. If done with minor problems, then validation can begin to occur at an earlier date than expected.

.png)

.png)

Figure 1: Price Quote for a 12” x 72” 304 Stainless Steel Sheet

Figure 2: Continuation of Stainless Steel Quote.

Figure 3: CFD Analysis Results of the Pressure Change During Gas Transfer.

Future Work Period of February 4th - February 17th:

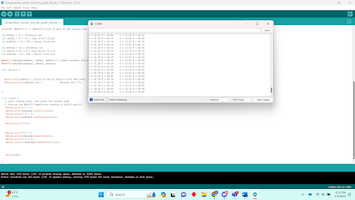

During the future work period, the team will be focusing on two main tasks which are the following. The team will receive the stainless steel material from the local vendor MetalSupermarket and take the material to the machinist for fabrication. The other main task is making sure all electrical components such as the thermocouples, gas sensors, and Arduino work. Figures 4 and 5 show what has been done so far which is the simultaneous use of multiple thermocouples at a time. Figure 4 shows two thermocouples, one in the open air and another in a cup of ice water. Figure 5 shows the results of the temperatures being outputted by the Arduino. Moreover, the team plans to create the final control system before fabrication is completed so it can be easily implemented once the finished device is retrieved from the machinist. This will allow the team to check for fitment issues with the wiring or instruments.

Figure 4: Arduino Setup with Two Thermocouples Used Simultaneously.

Future Obstacles:

During the next two weeks, one of the main problems the team foresees is related to the control system and the Arduino. As all the components are put together and connected, it will be unlikely that the control system will work as intended during the first run. For example, the code will most likely need to be troubleshooted multiple times to make sure that all four thermocouples are sending measurements simultaneously to the Arduino, allowing for the correct precautions to be taken such as the activation of the electromagnetic lock. Although the team sees this as an obstacle, it was expected and the correct measures are being taken to deal with it. The team plans to start ahead of schedule on the control system since almost all the components have been received already.

Figures of Progress:

bottom of page