top of page

Lithium-ion Battery Testing Chamber

Blog Post #6

Work Completed February 4 - February 17:

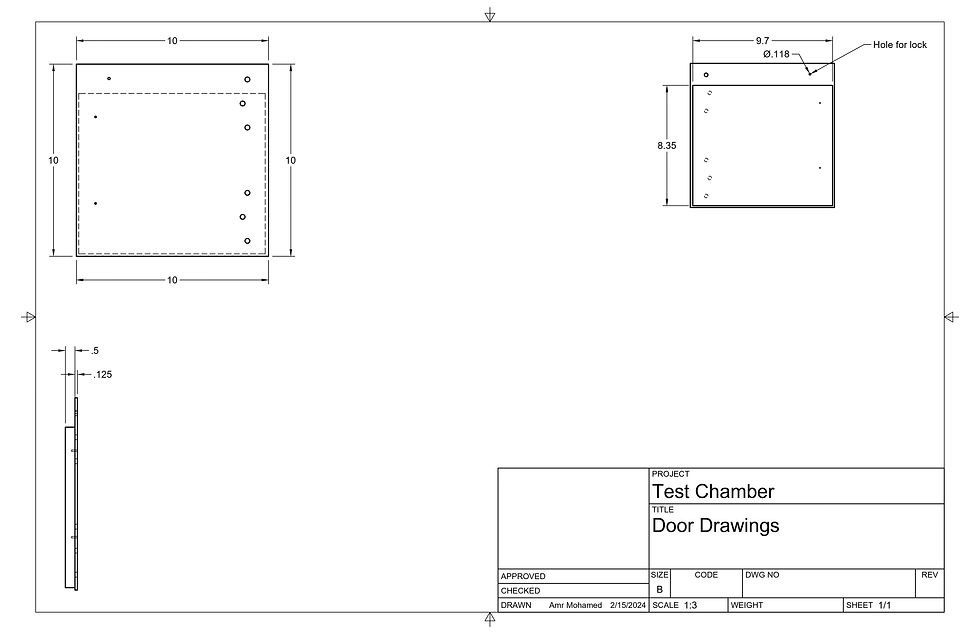

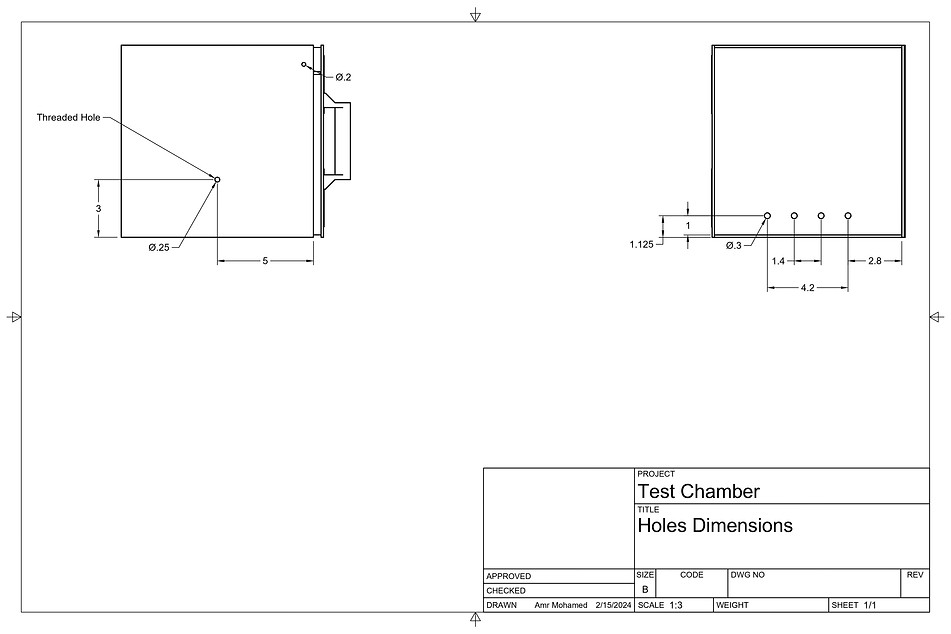

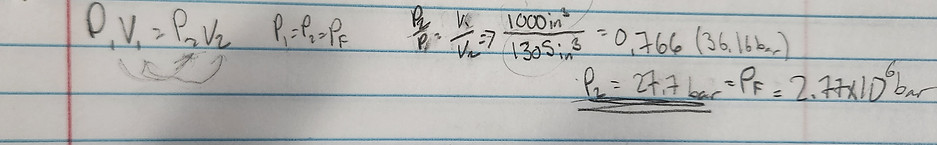

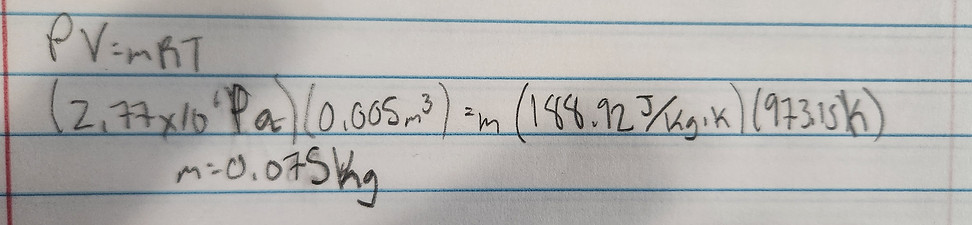

The Team’s focus for the work period between February 4 - February 17 was on finalizing the CAD design of the test chamber using 0.125 inch thickness in Fusion360, preparing the 2D drawings of the design to send it to the UH machinist and ordering the materials from Metal Supermarkets. The 2D drawings can be seen in the Figures section. After the team received confirmation from Dr.Song that the project will be funded by NOV, the stainless steel sheets were ordered. On February 14th, Metal Supermarkets notified the team that the ordered materials are ready to be picked up. The team also met with the UH machinist on Thursday 15th of February to finalize the design details and address any concerns or questions over the design before moving into the fabrication process. The team also acquired the address and details required to deliver the metal sheets and other components to the machinist. Under the assumption the team can deliver the sheets to the machinist by February 20th to start on the 21st, he'll be able to finish fabrication by March 4th at the latest which would be on track with the team's gantt chart. In addition, during this work period the team has conducted a few calculations using the ideal gas law to find the final gas pressure as well as the mass of the gas. The team is currently working on calculating the total volume of gas that will be ventilated up until the pressure equalizes inside and outside the chamber. This calculation will help with verifying that all the gas will be pushed out of the main chamber to the gas exhaust bags without the need for a pump or a fan. The mentioned calculations can be seen in the Figures section as well.

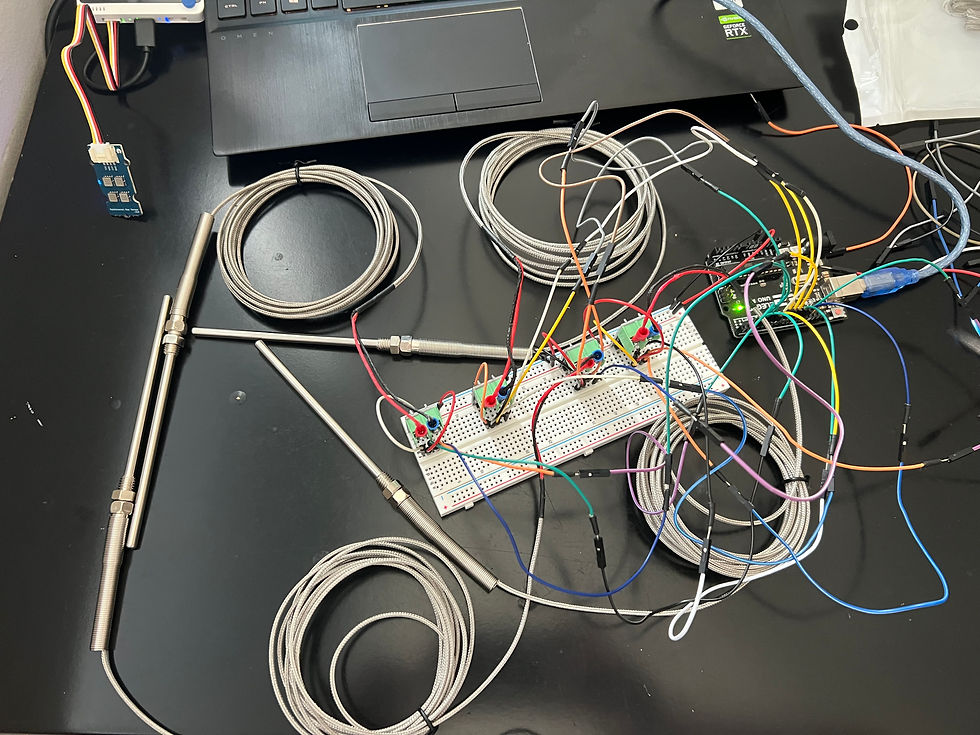

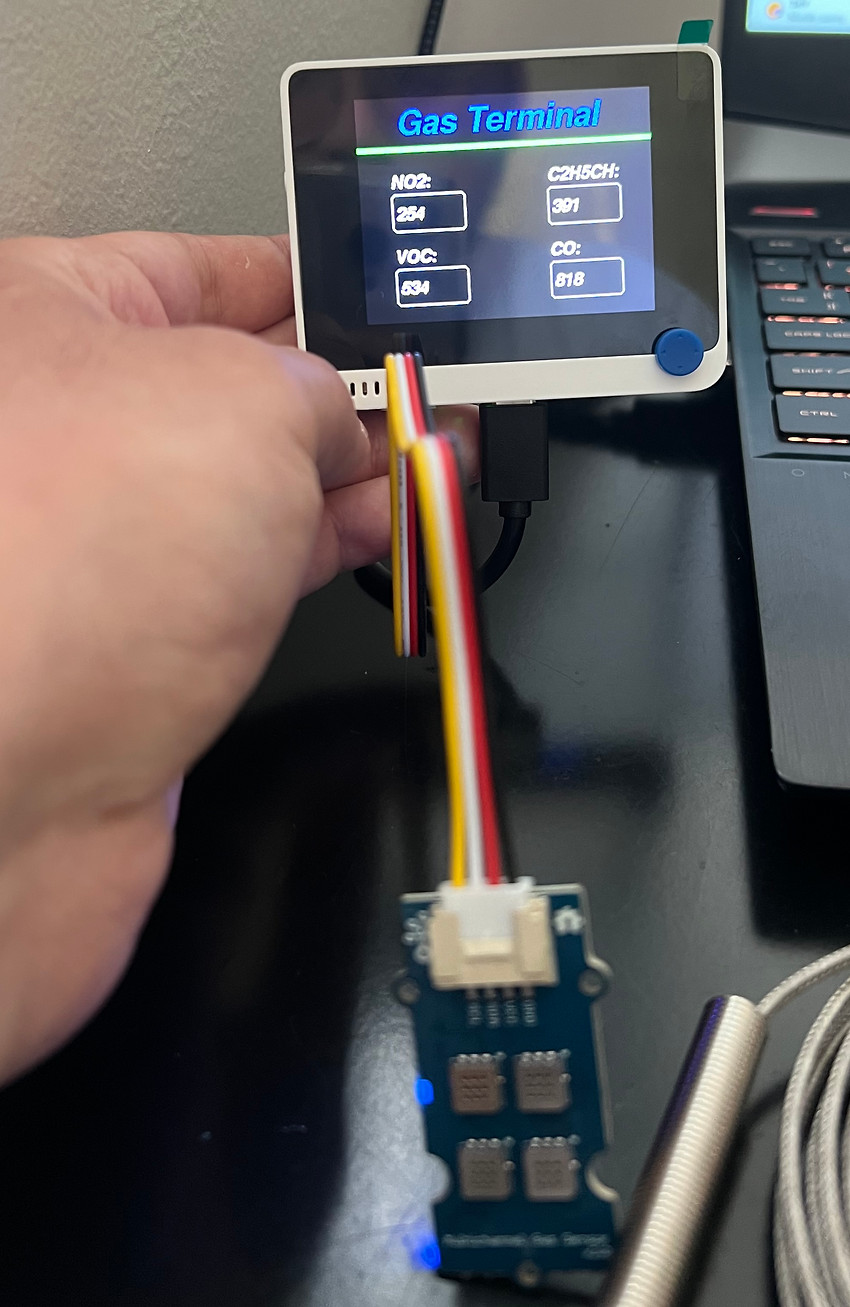

During the waiting period for the materials to be ready, the team furthered the development of the microcontroller system. This work consisted of getting temperature readings from all 4 thermocouples at the same time and getting readings from the gas sensor. From testing, the thermocouples work properly, but the gas sensor will need some calibration before accurate readings can be given. The mentioned progress for the microcontroller can be seen in the Figures section as well.

February 17 - March 9 Work Period Plans

For the work period of February 17 - March 9 the team plans to complete the design of the ventilation system and to continue to test instrumentation to ensure it is working properly. After consulting with the team’s capstone instructor, it has been determined that conducting a CFD analysis for the design of the ventilation system is far too complicated for the scope of this project. To simplify things, the team will begin doing basic ideal gas calculations to determine the best way to design the ventilation system. The team plans to continue to consult UH professors to assist with the calculations and provide insight into the best design of the ventilation system. The team will also use this time to remain productive while waiting for the machinist to complete the fabrication of the chamber. During this time, the team will be integrating the electromagnetic lock into the microcontroller system which will almost complete the electronic system being used. Once the team completes instrumentation testing, validates that all instruments work properly, and receives the fully fabricated chamber back from the machinist, the team will begin placing all necessary instrumentation inside the chamber. This will conclude all work tasks listed in Milestone 5.

Expected Obstacles:

The team only foresees 2 possible obstacles for the work being conducted over the next two weeks. The first obstacle would be officially completing the ventilation system design. As the team has recently changed the approach for the system design, the team has now had to apply many “assumptions” to conduct these ideal gas calculations. This may provide an obstacle further down the line during testing as the solutions obtained from the calculations are only “ballpark” solutions. Essentially the team will be obtaining information about gas in the chamber in the worst possible case scenario, which may not necessarily fit the realistic behavior of the gas. The other obstacle the team foresees would be if the machinist were somehow delayed in completing the fabrication of the chamber. The longer the team has to wait to receive the fabricated chamber from the machinist, the longer it will take for the team to complete Milestone 5. The team included buffer time in the project plan as a precautionary measure in case any unforeseen delays were to occur.

Figures:

Figures 1 & 2: Gas Flow Calculations

Figures 3 & 4: 2D Cad Drawings for Fabrication

Figures 5 & 6: Thermocouples and Gas Sensor

bottom of page